Delving into the world of mechanics, the gearbox is a fundamental component, a true workhorse in various applications. It’s the heart of any machinery, quietly ensuring efficiency and durability. This article serves as a deep dive into the fascinating world of gear products gearbox.

Gear Products Gearbox

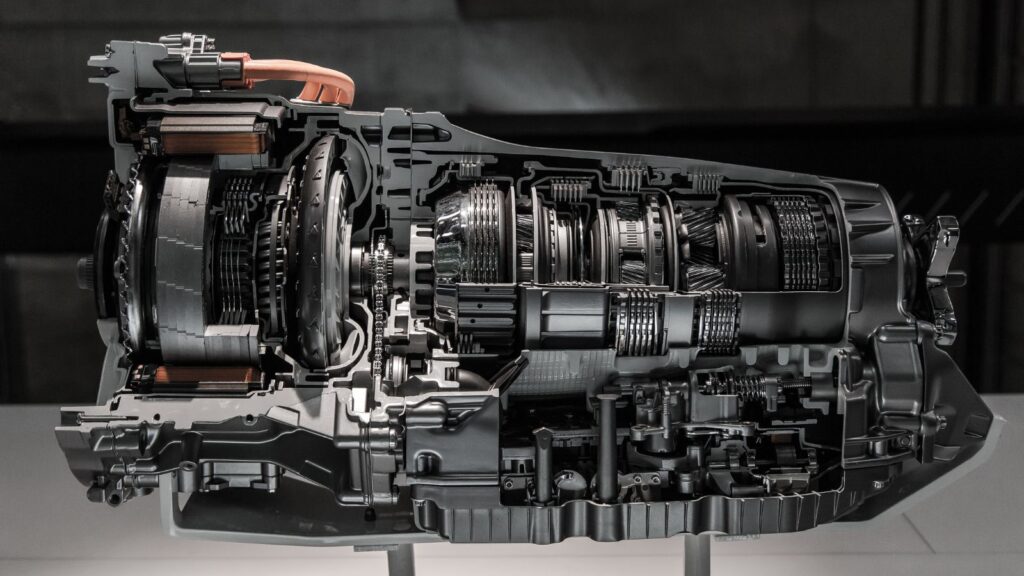

Dive deeper into the intricate world of gearboxes. Uncover the dynamics that influence their functions and the critical parts that make up these pivotal components.

Gear products gearbox serves vital functions in any mechanical setup, operating with a modulated rhythm that showcases its importance. It acts as an effective intermediary, aiding in the efficient transfer of energy from the engine to the intended parts. It regulates torque, a force that rotates an object about its axis. This regulation controls the rotational speed and direction, a key feature in machines for applications such as conveyor belts, lifts, and cranes.

For instance, gearboxes, in their role of speed governor, alter the vehicle’s dynamics. When the car accelerates, the gearbox helps in managing the engine’s RPM (Revolutions per Minute), ensuring that it doesn’t go above the permissible limit.

Gear Products Gearbox in Different Industries

Uses of Gear Products Gearbox in the Automotive Industry

Automobiles heavily rely on gearboxes for efficient operation. They’re essential in vehicles, regulating speed, enhancing control, and favoring seamless energy transfer from the engine to the wheels. In autos like cars, trucks, and motorcycles, gear product gearboxes serve as indispensable mechanisms, allowing smooth acceleration and performance.

For instance, in a standard car, the gearbox regulates engine rotation to wheel rotation, enabling the vehicle to run at different speeds. Similarly, in heavy-duty vehicles like trucks, gearboxes control torque, allowing the vehicles to carry heavy loads at a manageable pace.

Role of Gear Products Gearbox in Industrial Manufacturing

In industrial manufacturing, gear product gearbox are pivotal. They translate the motor power into a usable form, playing a crucial role in maintaining the efficiency and continuity of production lines. Their regulative abilities – controlling speed, handling torque, and managing energy transfer – are the driving factors behind their extensive use in this field.

As an example, in production lines, gearboxes synchronize the operation of different machinery, ensuring the consistent flow of production. In textile industries, they’re involved in spinning and weaving machine operations, directly influencing the quality of the end product. The robust design, durability, and high reduction ratios of gear product gearboxes render them ideal for such demanding applications, reinforcing their significance in industrial manufacturing.

Selecting the Ideal Gear Products Gearbox

Factors to Consider when Choosing Gear Products Gearbox

When choosing a gear products gearbox, you should scrutinize several significant factors.

- Load Characteristics: Observe the load characteristics of your machinery. In high-load applications, such as manufacturing or industrial production, she recommends opting for gearboxes that sustain heavy-duty use.

- Efficiency: The gearbox’s efficiency rating is another critical factor. High-efficiency gearboxes reduce energy loss, contributing to greener operation and cost savings in the long run.

- Installation environment: Consider where the gearbox is to be installed. For corrosive or extreme temperature environments, gearboxes made with suitable material prove to be the best choice.

- Maintenance requirements: Regular maintenance is key to prolonging the lifespan of the gearbox. Thus, easy-to-maintain gearboxes often score high on buyers’ lists.

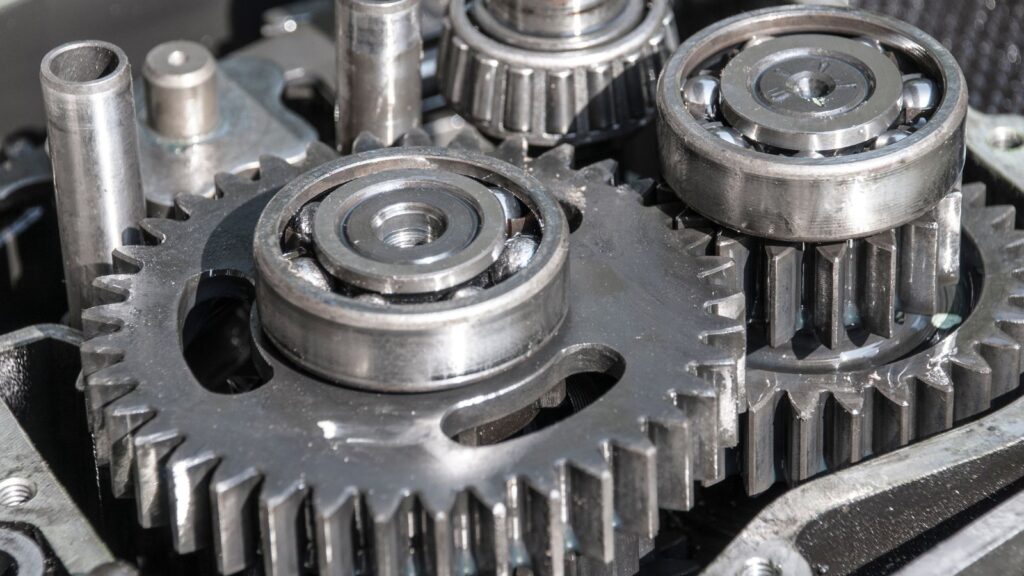

Importance of Gear Ratio in Gear Products Gearbox

Understanding gear ratio assumes central importance when selecting a gear products gearbox. Gear ratio, simply put, is the ratio of the rotational speeds of the first and last gear. It directly affects speed control and torque output. For example, a gearbox with a high gear ratio may not provide high speeds, but it generates more torque. Conversely, a gearbox with a low gear ratio could provide high speeds but may lack in torque.

So, the desired speed and torque output should guide the decision while considering the gear ratio of a gearbox.

Efficiency and Durability

The role gear products gearboxes play in enhancing machinery efficiency and durability is undeniable. They’re pivotal in energy transfer, torque regulation, speed control, and energy efficiency across diverse industries. Their selection requires careful consideration of load characteristics, efficiency, installation environment, and maintenance needs.